About Company

Qinghe County Zhenda Auto Parts Co., Ltd.is a professional foundry integrating casting, machining, heat treatment, and painting. The company was established in 2000 and is located in Chengguan Industrial Zone, Qinghe County. The factory covers an area of 15,000 square meters, and the company has 100 employees, including 15 technicians and more than 10 senior technicians. The annual production capacity is 6000 tons.

Focus on every detail

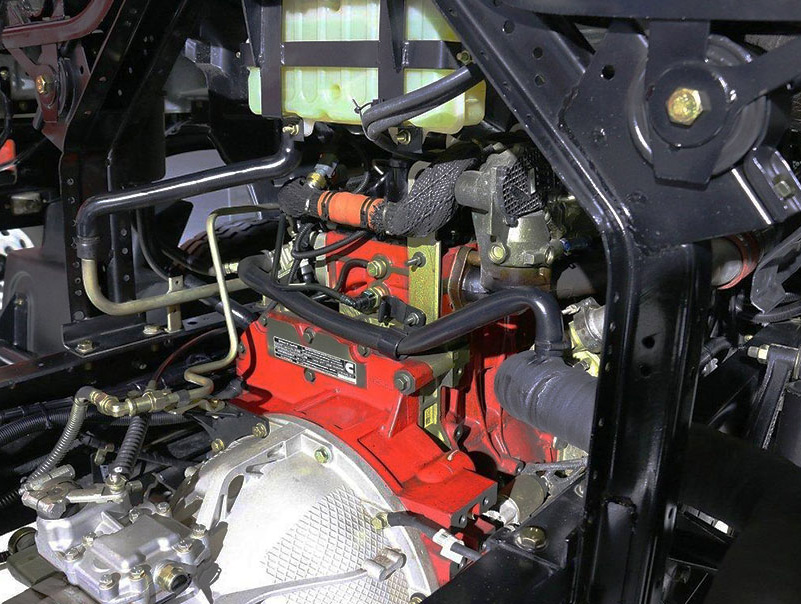

At present, Qinghe County Zhenda Auto Parts Co.,Ltd. produces more than 200 kinds of supporting products for Mercedes-Benz Heavy Duty Truck, adi casting products for Ingersoll Rand of the United States, adi casting gears for German Yost Auto Parts Co., Ltd., and large airroad for Australia There are more than 200 varieties of rear suspension system adi products for heavy-duty vehicles and ordinary ductile iron products for Changan Heavy Duty Truck.

Our company mainly focuses on iron castings. The parts produced are widely used in the manufacture of heavy-duty and wear-resistant parts for automobiles, railway equipment, general machinery, construction and mining machinery. Such as: ball mill ball, liner; heavy-duty automobile spring support, crankshaft, gear; wedge, wear plate and wear-resistant pin sleeve of shock absorption system of railway freight car bogie; general machinery, construction machinery, gear, track plate and other parts .

At the same time, austempered ductile iron castings can widely replace steel castings and forging steel parts. Compared with them, it not only reduces the process and saves man-hours, but also has better performance than steel castings and forging steel parts.

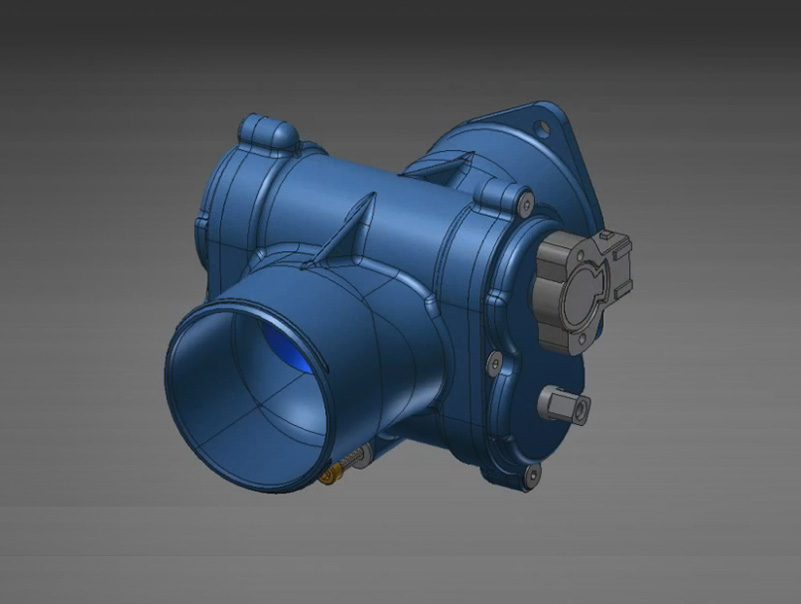

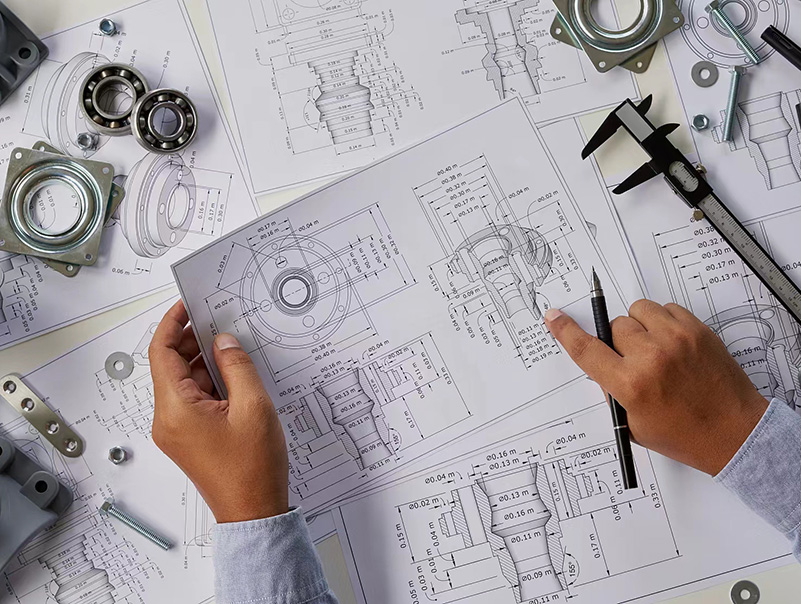

Our company can customize the parts required by customers according to their needs. You can analyze and design products through 3D drawings, plan drawings, and samples, and produce high-quality products more accurately. In addition, our company has the strength to develop OEM parts. If you have any needs in this regard, you can also contact us

Select branded raw material suppliers to control quality from the source.

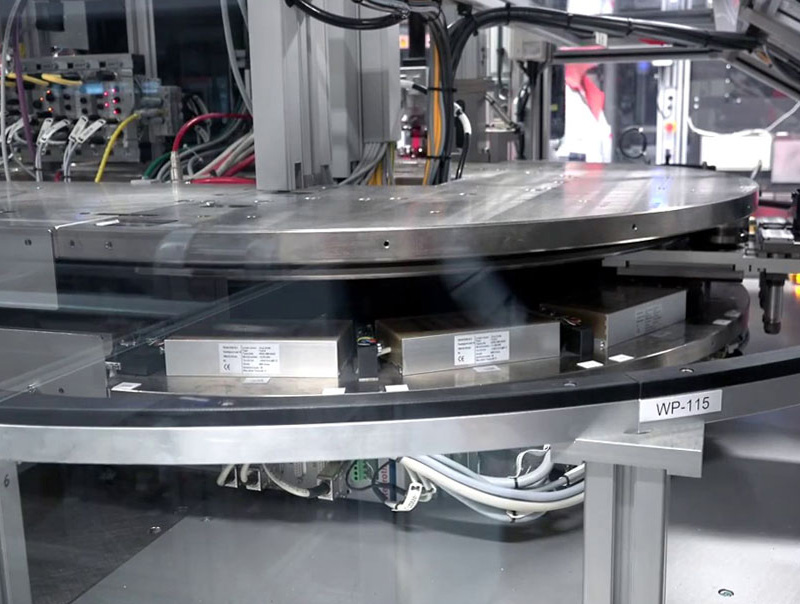

A full set of imported testing equipment

A capable quality inspection technical team.

Each batch of products is fully tested and a detailed test data report is provided.

Walk hand in hand, shape the future with you